In response to the evolving security challenges in global air cargo transportation, aviation security screening technologies have significantly advanced in recent years. In 2024, the Civil Aviation Administration of China (CAAC) introduced the world’s first technical standard for Computed Tomography (CT) explosive detection systems for air cargo containers. Following this, NUCTECHTM CTitan, a next-generation CT screening system for Unit Load Devices (ULDs) and cargo pallets, became the first security solution to be certified under this standard. This breakthrough enhances the industry’s ability to screen ULDs and palletized cargo efficiently while maintaining high-security standards.

![]() Overcoming Screening Limitations

Overcoming Screening Limitations

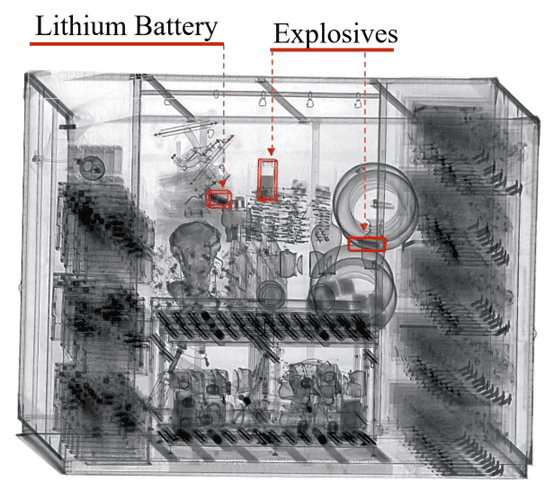

Traditional X-ray screening systems face significant challenges when inspecting air cargo containers, as the 2D images they generate suffer from limited penetration and overlapping views, making threat detection difficult. As a result, cargo is often required to be broken down into smaller units for individual screening, causing delays in security procedures and logistics operations.

CTitan, featuring stationary CT technology and an expansive tunnel design measuring four meters in width and three meters in height, addresses these challenges by enabling the screening of fully loaded ULDs and palletized cargo without disassembly. The system generates high-resolution, 360-degree rotatable 3D images, along with CT slice images and enhanced 2D views, ensuring comprehensive cargo visualization with no blind spots.

Compared to conventional X-ray machines, CTitan provides detailed analysis of physical properties, including density distribution, object shape, texture, and more. This allows for the automated identification of a broader range of high-risk items, including explosives, lithium batteries, and other aviation-focused threats, significantly enhancing air cargo security and operational efficiency.

![]() Enhancing Air Cargo Container Screening Efficiency and Effectiveness

Enhancing Air Cargo Container Screening Efficiency and Effectiveness

The certification of CTitan was completed over an 18-month period through close collaboration among industry regulators, technology providers, and airport security authorities. This process focused on optimizing system performance, enhancing screening procedures, and aligning security operations with evolving regulatory requirements, ensuring the safe and effective deployment of large tunnel CT screening technology for air cargo containers.

The introduction of CTitan represents a major advancement in addressing longstanding industry challenges. Previously, due to limitations in available screening technologies, large-size cargo often had to be held—sometimes for over 24 hours—until security screening could be completed. CTitan now enables immediate screening upon arrival, streamlining processing and reducing airside congestion.

With CTitan, these cargo can now be scanned immediately upon arrival, significantly reducing processing times and optimizing airside storage utilization. Additionally, the system demonstrates outstanding performance in the rapid screening of cold chain shipments, effectively minimizing prolonged exposure risks that could impact cargo quality.

A key advantage of CT technology in air cargo container screening is its ability to generate high-resolution 3D imagery, enabling detailed inspection of consolidated shipments. In e-commerce cargo, items such as smartphones and e-cigarettes can be individually identified within bulk shipments in the screened images, ensuring compliance with cargo manifests and regulatory requirements. The ability to conduct non-intrusive screening without requiring physical unpacking enhances both screening efficiency and supply chain security.

Future Outlook: Transforming Air Cargo Container Screening

Beyond aviation security, the application of large tunnel CT screening technology holds significant potential for enhancing collaboration between aviation and customs authorities. High-definition 3D imaging and AI detection capabilities allow for the non-intrusive examination of entire ULDs, enabling authorities to detect prohibited or undeclared goods without the need for manual breakdown. By using the same technology, aviation and customs can streamline the clearance process, reducing processing times at both airport and customs checkpoints. This collaboration can accelerate air cargo transportation, strengthening global trade security and improving supply chain efficiency.

Looking forward, as global e-commerce and cross-border trade continue to expand, the integration of CT-based cargo screening with emerging technologies such as IoT and big data analytics will further enhance cargo screening intelligence and transparency. The application of large tunnel CT technology may extend beyond aviation checkpoints to bonded logistics zones, express cargo hubs, and major freight terminals, supporting a more seamless flow of goods and facilitating the continued growth of global air trade.

About the Author

NUCTECH was founded in 1997 by a group of scientists from China’s top university Tsinghua. They brought decades of research findings from the lab to the field to solve pressing security issues at airports, ports, borders, secured facilities and public events around the world. Deeply rooted in academia, it is an organization that prides themselves on innovation. NUCTECH invests heavily in R&D. Every year, more than 10 per cent of their annual revenue is directed to present and future-oriented research. They commercialize those technologies and develop over 300 models of inspection systems and solutions. Based on a deep understanding of security needs in the real world, we are, always on the way to bringing security to life. They have deplaoyed more than 50,000 systems have been deployed in over one hundred and seventy (170) countries to safeguard travel, trade and transportation around the world.

NUCTECH was founded in 1997 by a group of scientists from China’s top university Tsinghua. They brought decades of research findings from the lab to the field to solve pressing security issues at airports, ports, borders, secured facilities and public events around the world. Deeply rooted in academia, it is an organization that prides themselves on innovation. NUCTECH invests heavily in R&D. Every year, more than 10 per cent of their annual revenue is directed to present and future-oriented research. They commercialize those technologies and develop over 300 models of inspection systems and solutions. Based on a deep understanding of security needs in the real world, we are, always on the way to bringing security to life. They have deplaoyed more than 50,000 systems have been deployed in over one hundred and seventy (170) countries to safeguard travel, trade and transportation around the world.

Enhancing Air Cargo Container Screening Efficiency and Effectiveness

Enhancing Air Cargo Container Screening Efficiency and Effectiveness